Applications

CF inflow mesh fine screen is applicable to the process of separating solids from liquids. It can be widely used in the pre-treatment process and advanced treatment process of reclaimed water of wastewater treatment plants which need new construction, reconstruction, water quality upgrading, technical transformation and upgrading. It can also be used in pre-treatment of tap water and process water in textile, paper-making and other industries.

Structure Principle

CF inflow mesh fine screen consists of racks, a driving system, a mesh system, a backwash system, a slag-removal system and an electronic-control system. The gear motor drives the sprocket wheel to rotate. The wheel leads the mesh for continuous rotation. The sewage enters the screen from the water inlet and is then filtered through the mesh. The filtered water flows outward the screen and the pollutants are intercepted on the inner surface of the screen and then taken to the top via continuous rotation of the mesh. The backwashing system flushes the outer surface of the mesh so the pollutants are flushed to the slag-collection tank and discharged out of the drain outlet.

Benefits Of inflow mesh fine screen

It can remove fiber materials like hair with high removal rate;

Backwash water removes the pollutants on the screen so that they won’t mix with the filtered water. In this way, secondary pollution can be avoided;

Screen adopts non-metallic plastic injection molding parts, featuring wear resistance and corrosion resistance;

It is easy for check and maintenance with no underwater transmission parts;

Standardized wearing parts are easy for replacement and operation;

It features stable operation, light vibration and low noise.

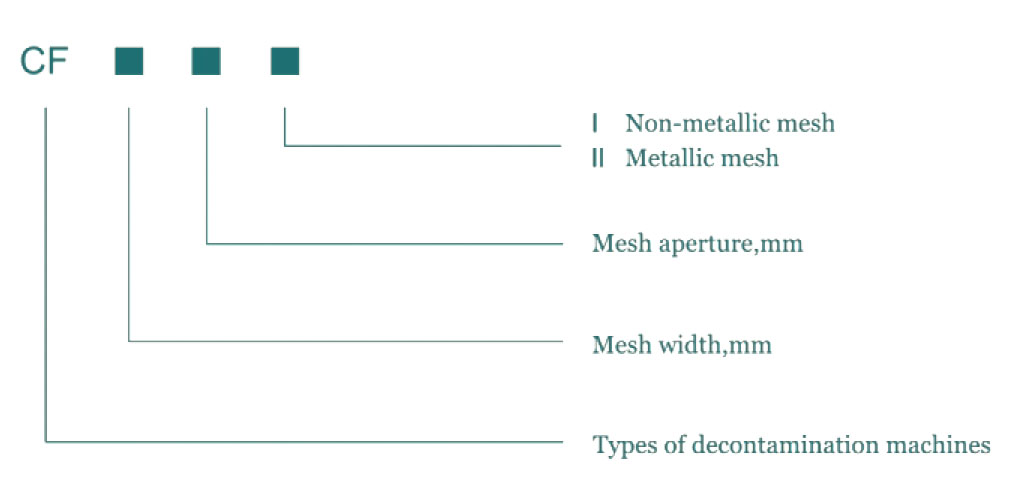

Model Label And Example

Example: CF1500/03 refers to the inflow mesh fine screen with mesh width of 1,500mm and mesh aperture of 3mm.