The efficient and compact settling tank works at a rising speed of 40m/h, removing phosphorus and SS at an extremely high rate. With small floor space, it saves investment.

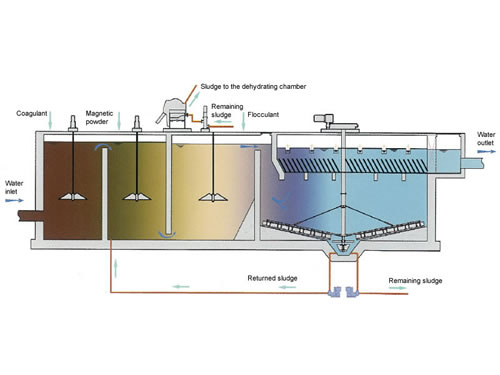

Process flow diagram of efficient magnetic coagulation settling tank

High gradient magnetic field which captures the passing magnetic particles is created on the surface of the magnetic media under external magnetic field so as to purify the treated water. The settling tank consists of high-speed coagulation area, mixing area of magnetic powder, flocculation tank, efficient settling tank, magnetic powder recycling, sludge backflow and discharge system, etc.

The water from the secondary settling tank goes to the coagulation area of fast blending after water distribution system. Ferric salt or aluminum salt is added near the paddle of the blender as coagulant which is then dispersed in the wastewater quickly and homogenously for hydrolysis. By this way, the coagulant collects the particles under the charge neutrality and destabilization on colloid electron in water by high charge of coagulant.

Proper magnetic powder is dosed in the magnetic powder mixing area. As the crystal nucleus, magnetic powder particles tend to form alumen ustum, significantly enhancing the amount of alumen ustum and settling speed.

The sludge returned from the bottom of the settling tank is delivered to magnetic powder mixing area via the pump. The circulating sludge is added so that SS could combine with sludge in raw sludge to form alum floc and recycle the magnetic powder of the system.

The sewage flows from magnetic powder mixing area to flocculation area. Macromolecule flocculant is dosed in the flocculation area so that SS can form larger and denser alum floc. With absorption and bridging functions, flocculant can make particles into larger alum floc for separation between solid and liquid so as to remove suspended substances and colloid.

The sludge after treatment in flocculation area will flow to efficient settling area which adopts the principle of shallow layer sedimentation and inclined tubes to significantly enhance the hydraulic surface loading in the settling area.

The sewage flows upward and the particles settle in the tank bottom. The scraping fender rotating centrically scrapes the sludge to the center of the bottom and push the sludge to the mud bucket. The sludge extracted from the bucket and delivered to the magnetic powder mixing area by the sludge circulating pump is called circulating sludge. And the remaining sludge will be delivered to the magnetic separator by the pump. The magnetic powder will be recycled and the rest sludge will be transported to the sludge processing workshop.

The online continuous high-speed and efficient magnetic mud shearing machine manufactured by Jiangsu Longqiao Environmental Protection Machinery Co., Ltd. is upgraded from the ordinary shearing machine characterized by unthorough dispersion between magnetic powder and sludge, short service life of sealing elements. Longqiao products have the following characteristics:

1. Motor specification: 1,450r/min (ordinary shearing machine:500-600r/min);

2. Shear knife is designed in the inner barrel (ordinary machine has no shear knife). When the shearing impeller drives the magnetic mud to rotate at a high speed in the barrel, the mud crashes with the shear knife for high speed shearing and hence separating the magnetic powder from sludge.

3. The sealing element uses special alloy thickened rotating ring and stationary ring which are the core parts of the sealing elements, with service life of over 9,000 hours.

| Model | JQJ-20 | JQJ-60 |

| Processing Capacity | 5-20m³/h | 25-60m³/h |

| Motor Power | 3kW | 4kW |

| Motor Revolvig Speed | 1,450r/min | 1,450r/min |

Functions: The separator is used to recycle magnetic powder of specific granularity, grade and quality from serous sludge.

Working principle: The sludge containing magnetic powder will be conveyed to the magnetic separator via the delivery pump. The strong magnetic roller, the core component of the separator, will absorb and separate the magnetic powder for recycling. And the sludge will be transported to the sludge treatment facility.

| S/No. | Model | Processing Capacity: m3/h | Motor powder: kW | Size: mm |

| 1 | CFJ-10 | 10 | 0.75 | L*W*H:1600*1000*1800 |

| 2 | CFJ-20 | 20 | 1.1 | L*W*H:1600*1300*1800 |

| 3 | CFJ-30 | 30 | 2.2 | L*W*H:1600*1600*1800 |

| 4 | CFJ-40 | 40 | 3 | L*W*H:1600*1900*1800 |

| 5 | CFJ-56 | 56 | 4 | L*W*H:1600*2200*1800 |

| 6 | CFJ-65 | 65 | 4 | L*W*H:1600*2600*1800 |

SS removal efficiency: ≤5mg/L

Total phosphorus removal efficiency: ≤0.3mg/L

It can remove insoluble COD efficiently.

- 15-40m/h ascending flowrate

- High removal rate of SS/TP

- Little influence of hydraulic load change

- Dose different types of media to remove COD at a higher rate and enhance outlet index of COD.

- Fast equipment start-up

- Recyclable magnetic powder, high recycling rate, reducing costs

- Low operation costs, saving 10%-50% dosage compared with traditional flocculation process

- Fully automatic control

- Less maintenance equipment

- Premium effluent quality, high stability

- Low sensitivity to temperature and water quality change

- Meet different requirements of effluent quality in accordance with inlet and outlet conditions and combinations of chemicals

- Ultrafast settling speed and excellent efficiency, saving infrastructure investment and floor space

- Simple process to replace the traditional process of normal coagulating sedimentation + filtering tank